The construction of twinax cables is a delicate process, that requires high precision and sensitivity in controlling the tension of core, drain wire and tapes.

WTM has developed a specific cable taping machine to this kind of product: the final result is a twinaxial conductor with low-loss and high transmission speed rate, that fully meet the requirements for data transmission cables used in Data link layer, 100Gbit Ethernet, SFP+, Ethernet, SATA 3.0, Display Port, etc.

The layout of the twinax cable taping machine usually includes:

- One or more pay-off units for cores, depending on the twinax cable shape;

- Pay-off unit for drain wire, if necessary;

- One or two longitudinal taping units, if required;

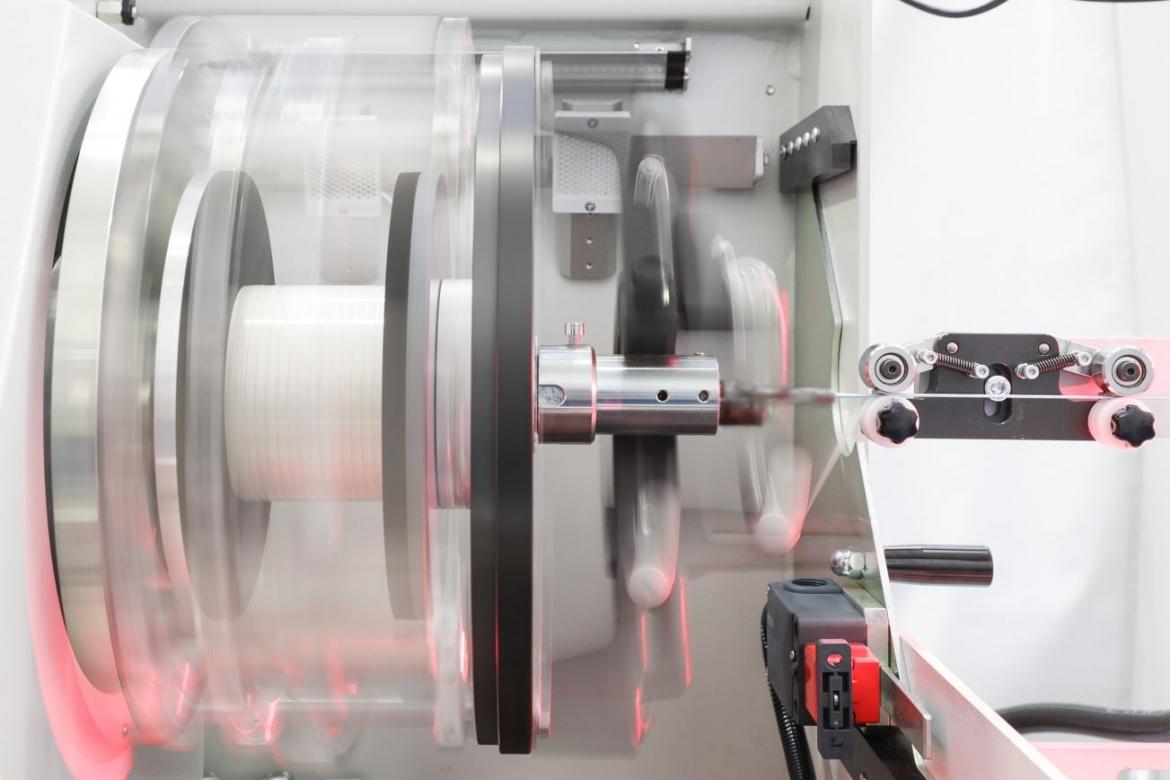

- Two taping units, respectively for the screening and for the sealing tape application;

- Double wheel capstan as synchronized pulling unit;

- In-line infrared sintering ovens, placed and set according to the finished cable characteristics;

- Comprehensive quality control system, composed by laser gauges, load cells and WTM Visio System, in order to manage the final product certification;

- Take-up unit, torque controlled, provided with traversing system for accurate cable distribution.

WTM supports the Customers in the choice of the most suitable solution, according to specific production needs, in the wide range of twinaxial cable constructions.

Request further information or a detailed quotation now!

Information Request