The basis of the perfect cable taping and spinning process is the absolute control of the tension of the wrapping material, combined with the precision of the tape deposition pitch

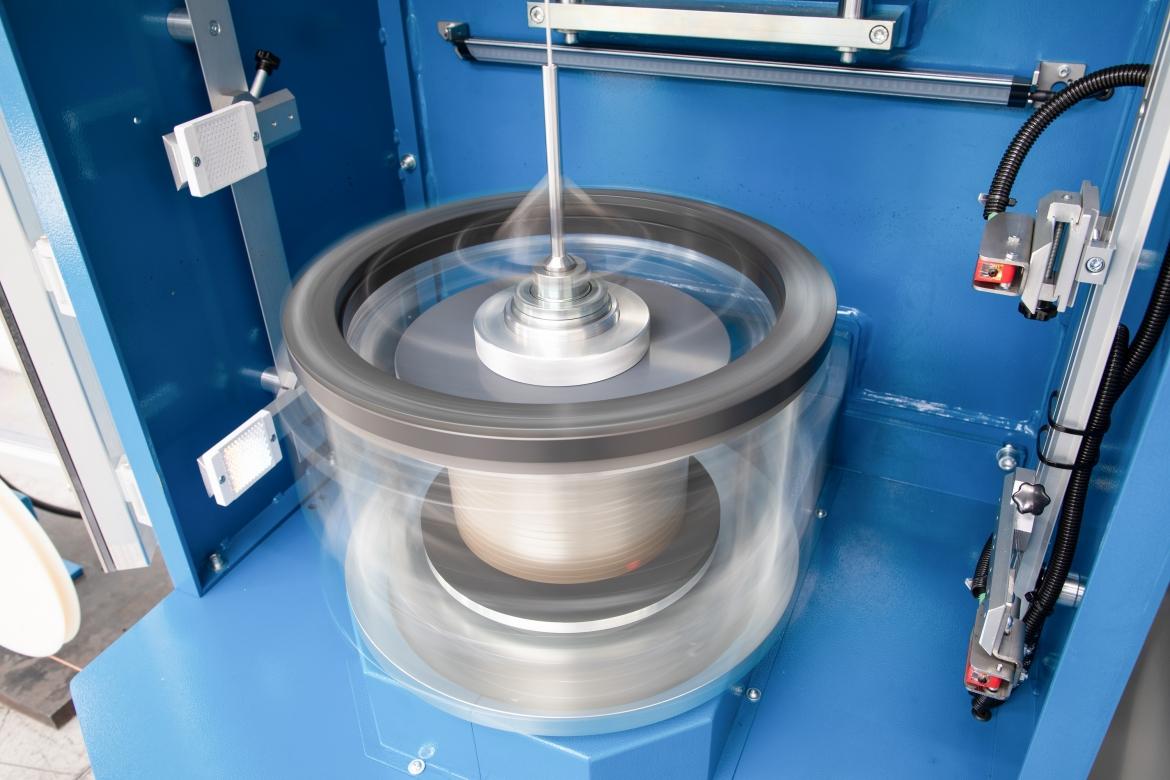

WTM has developed a complete range of concentric wire taping and spinning heads, suitable for tape pads and cross wound spools.

Depending on the technology underlying the tape tension management, WTM taping heads can be divided as follows:

- wrapping heads with DIRECT tension control: WTM DYNAMIC dancer acts on the material just immediately before its application;

- taping heads with INDIRECT tension control: the tape tension is managed by means of a motor and torque control.

WTM offers different types of cable wrapping heads also according to their motorization:

- in the heads with single motorization, the dancer adjusts the mechanical braking friction;

- in the fully motorized taping heads, the electronic dancer controls the tension of the material through the synchronization between wrapping head and pad or spool.

The technical characteristics can be customized according to the specific production requirements of the Customer.

Request further information or a detailed quotation now!

Information Request