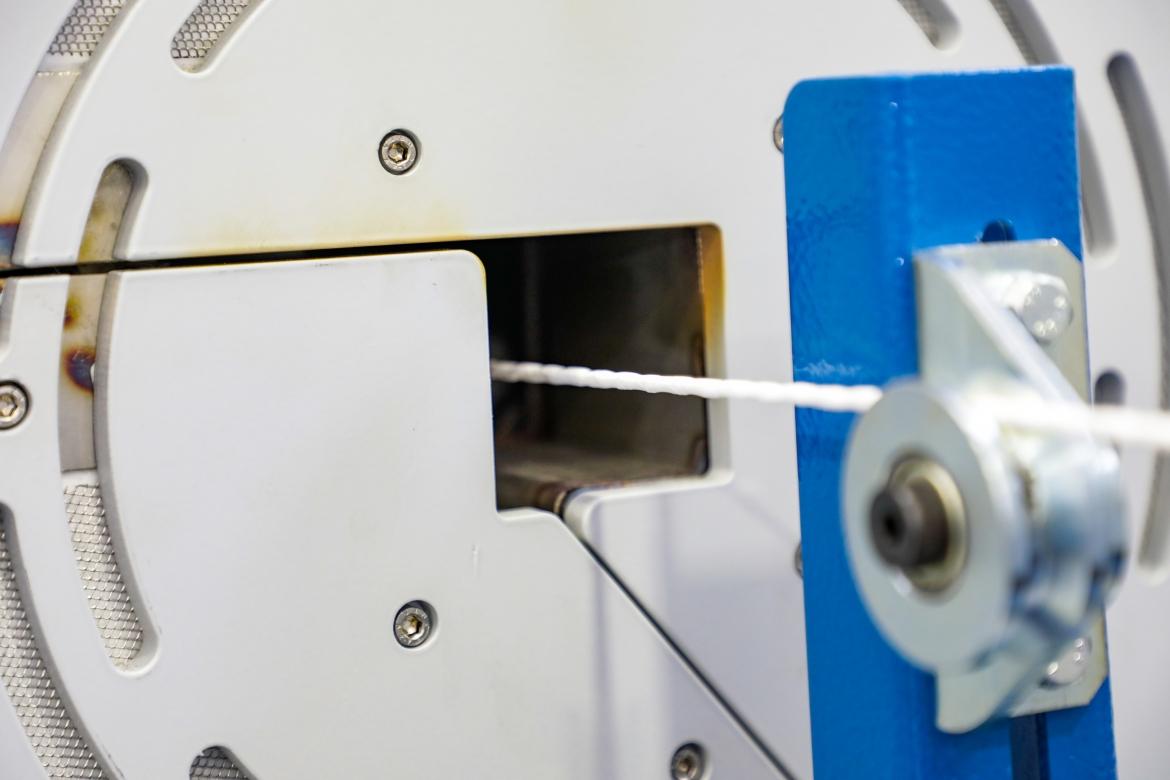

In order to meet the need to seal taped cables for completing the conductor production process, WTM has developed sintering ovens with infrared technology.

The infrared sintering ovens can be purchased individually and integrated into existing wire taping equipment or cable rewinding lines.

Main features:

The infrared sintering ovens can be purchased individually and integrated into existing wire taping equipment or cable rewinding lines.

Main features:

- Automatic opening/closing system

- Onward and backward movements during start/stop phases, in order to avoid the cable burning

- Different configuration and dimensions: 1.5, 2 or 3 meters of ength

- 3 or 4 independent sintering zones

Technical details:

- Maximum temperature: 450 °C (1,5-meter long oven) or 550 °C (3-meter long oven)

- Heating tunnel insulated with mineral and ceramic fibres, which external surface not exceed 80-100 °C

- Dedicated thermocouple for each infrared radiating panel, connected to the PLC for its integrity checking

- SCR “zero crossing” regulators and thermocouple sensor control for each sintering zone

Equipment ot complete the sintering line:

- Cooling and drying units (by air or by water)

- Induction pre-heating system

WTM supports the Customers in the choice of the best sintering solution, according to the specific production needs.

Request further information or a detailed quotation now!

Information Request