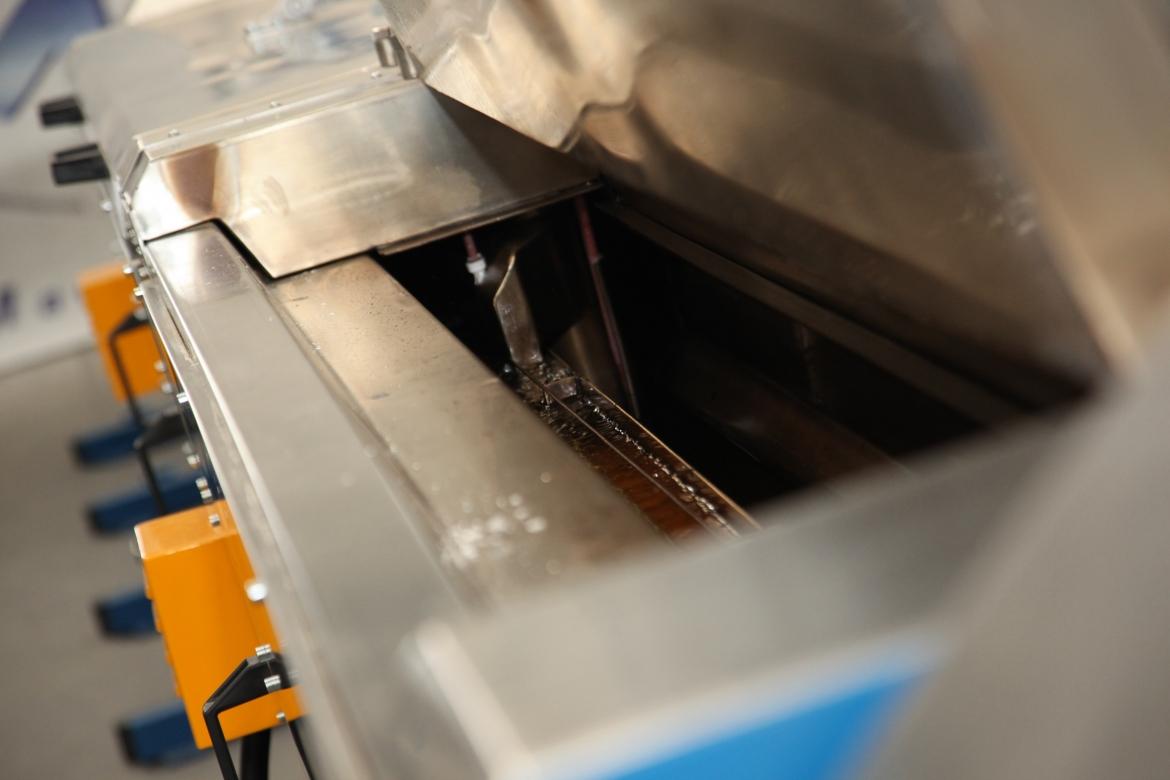

Advanced sintering and sealing process suitable for PTFE, polyimide, FEP, slicon and other cable insulating materials, obtained deepening them into a high temperature molten salt bath.

The wires to be treated are driven through the sintering oven inside the working tank, which is fed by an axial pump that takes the salt from the melting tank placed below. Special heating elements keep the salt temperature under control. Once the treated cable exit the oven, the residual salt on the wire surface is washed away and the conductor is cooled and dried at once.

The sintering ovens completes WTM rewinding lines: up to 4 wires, even with different dimensions and speeds, can be simultaneously treated with the same salt bath oven.

The technical characteristics can be customized according to the specific production requirements of the Customer.

Request further information or a detailed quotation now!

The wires to be treated are driven through the sintering oven inside the working tank, which is fed by an axial pump that takes the salt from the melting tank placed below. Special heating elements keep the salt temperature under control. Once the treated cable exit the oven, the residual salt on the wire surface is washed away and the conductor is cooled and dried at once.

The sintering ovens completes WTM rewinding lines: up to 4 wires, even with different dimensions and speeds, can be simultaneously treated with the same salt bath oven.

The technical characteristics can be customized according to the specific production requirements of the Customer.

Request further information or a detailed quotation now!

Information Request