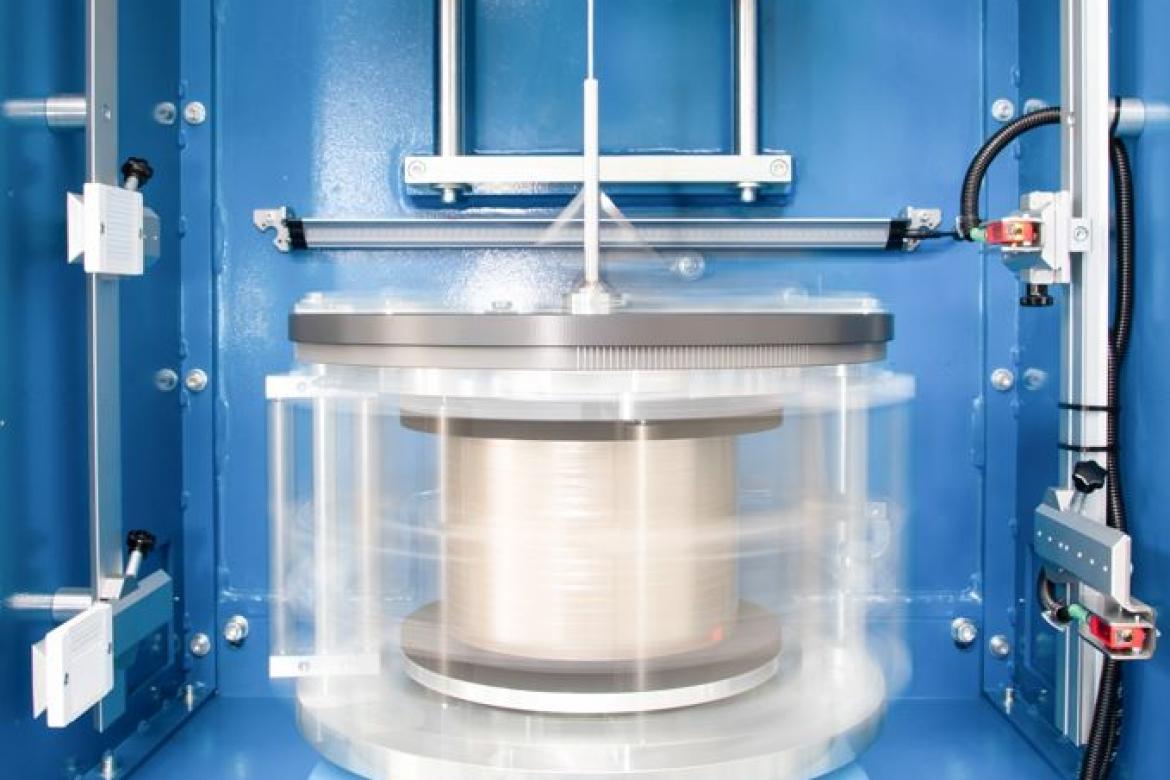

For the production of cables for which the possibility of bending the conductor itself is not a problematic condition, WTM offers the possibility of having the cable taping machine with vertical layout.

This solution reduces the space occupied in production by the taping machine, maintaining the performance unchanged.

The vertical cable taping machines are very versatile:

- They are suitable for the application of any kind of tape and yarn (mica, polyamide, polyimide, PTFE, paper, polyester, laminated tapes, aluminum foil, metal, fiberglass, etc.), both on single or stranded conductors, and on mono or multipolar cables.

- The cable taping heads can work both with tape spools and pads.

- Each taping column can be equipped with one or two taping heads, saving further space in production

The layout of the vertical taping machine is composed by:

- cable pay-off unit, with cantilever or shaft design, even with traversing movement, with wire tension managed by dancer or torque control;

- one, two or more vertical taping units;

- cable taping heads (one or two in each taping column);

- pulling capstan, for the synchronization between taping head rotation speed with the line speed;

- cable take-up unit, with cantilever or shaft design, even with traversing movement, with wire tension managed by dancer or torque control.

The technical characteristics can be customized according to the specific production requirements of the Customer.

Request further information or a detailed quotation now!

Information Request