WTM’s core business is the design and supply of machines for the production of high quality cables.

Particular attention is paid to the process for producing aeronautic cables and high frequency data cables, employed in the field of aerospace and cloud technology.

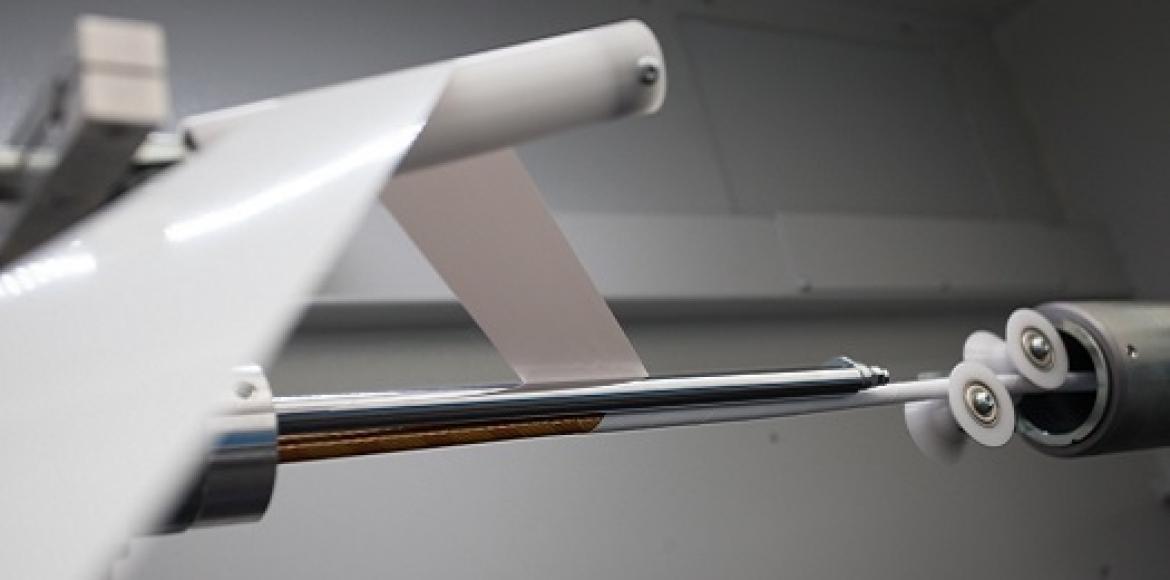

Over the years, WTM has developed specific solutions that fulfill the requirements of Customer leader for this kind of product. WTM has recently improved the performances of its high speed taping heads with updated design, providing an extremely accurate tension control even for flat cables, using materials and technological solutions specific of aeronautic industry.

The same care has been paid to the precise cable tension control on take-up and pay-off systems, that work with feedback signal and without the use of dancers (thus, without any cable bending), with the aim of preserving the cable quality.

WTM, as Italian leader of taping, wrapping and sintering processes for cable production, will participate to the great showcase offered by Wire 2018 exhibition in Düsseldorf and will display a machine that includes all these features. The taping line will be composed of self-aligning and self-levelling take-up and pay-off units (avoiding any torsion or bending on the cable) and two wrapping units, the first for twinaxial cable spiralling and the second for aeronautic cables taping.

The machine is completed with a supervision system provided by three laser gauges and two cameras, coordinated by a real-time monitoring system that is able to give also the statistic analysis of the full process.

Stopping by WTM stand 11D78, you will have the opportunity to see this machine WORKING, to meet WTM staff, to discuss about your production requirements and learn more about the whole WTM production range of taping equipment, twisting lines and curing systems for high quality cable production. We wait for you!

Particular attention is paid to the process for producing aeronautic cables and high frequency data cables, employed in the field of aerospace and cloud technology.

Over the years, WTM has developed specific solutions that fulfill the requirements of Customer leader for this kind of product. WTM has recently improved the performances of its high speed taping heads with updated design, providing an extremely accurate tension control even for flat cables, using materials and technological solutions specific of aeronautic industry.

The same care has been paid to the precise cable tension control on take-up and pay-off systems, that work with feedback signal and without the use of dancers (thus, without any cable bending), with the aim of preserving the cable quality.

WTM, as Italian leader of taping, wrapping and sintering processes for cable production, will participate to the great showcase offered by Wire 2018 exhibition in Düsseldorf and will display a machine that includes all these features. The taping line will be composed of self-aligning and self-levelling take-up and pay-off units (avoiding any torsion or bending on the cable) and two wrapping units, the first for twinaxial cable spiralling and the second for aeronautic cables taping.

The machine is completed with a supervision system provided by three laser gauges and two cameras, coordinated by a real-time monitoring system that is able to give also the statistic analysis of the full process.

Stopping by WTM stand 11D78, you will have the opportunity to see this machine WORKING, to meet WTM staff, to discuss about your production requirements and learn more about the whole WTM production range of taping equipment, twisting lines and curing systems for high quality cable production. We wait for you!

Information Request