This taping machine, with horizontal design, offers an accurate application of various layers of expanded PTFE tape: the final result is a conductor with dielectric insulation, that can be further screened for obtaining high frequency coaxial cables.

The machine can be equipped with different taping units, up to five, that insulate the conductor with ePTFE of different dimensions, until the desired dielectric thickness is obtained.

Each taping heads applies tapes (from both spools and pads) with different density and thickness, and the overlapping is determined according with the number of layers required in each specific application.

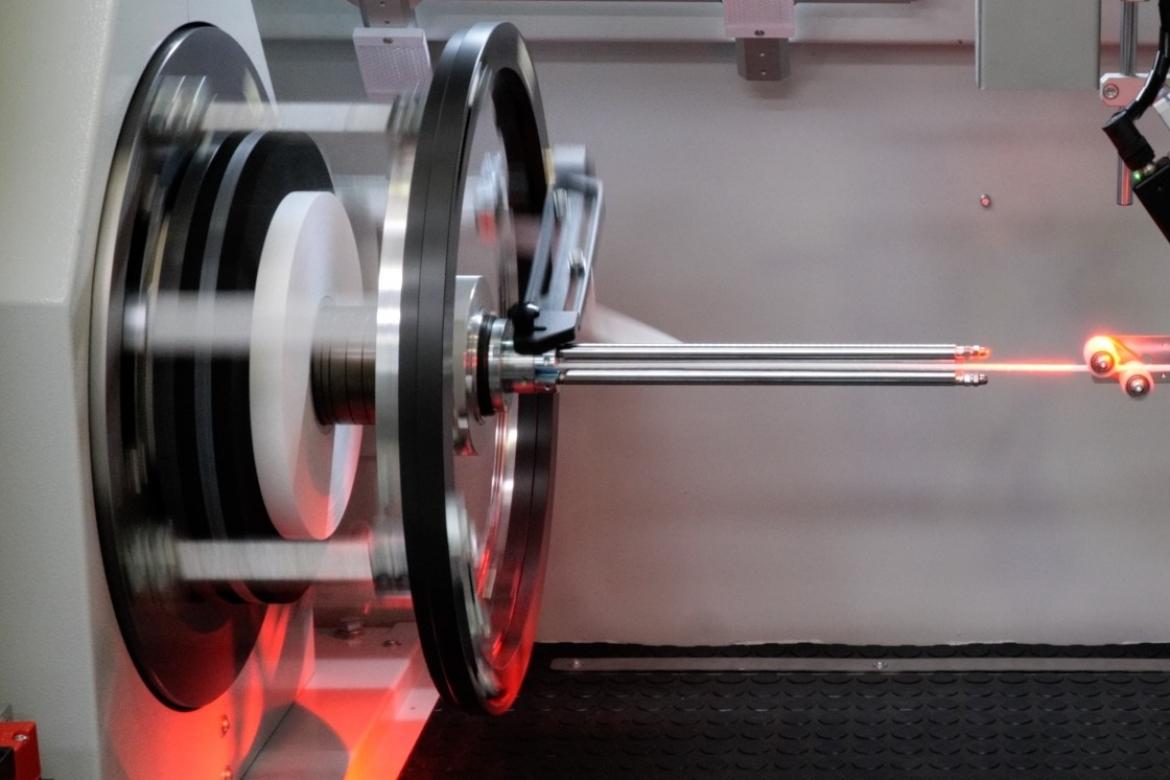

WTM calibrating systems grant total smoothness and perfect concentricity of the cable after each tape application: dual-axis laser gauges, positioned after each taping unit, inspect the quality of the cable processed.

On request, the machine is supplied with Visio System, our visual inspection system with cameras, which measures the taping pitch and angle in each production step. The system is completed by WTM dedicated software for statistical analysis (Statistical Process Control) and in frequency through FFT analysis of the various production parameters (taping pitch, cable and tape tension, cable diameter, speed, synchronisms, etc.), both online and with data collection for post-processing. An accurate report on the collected data is provided at the end of the production batch.

This specific machine configuration is as follows:

- pay-off unit with specific tension control, through dancer and loadcell or motor torque control with feedback by torsiometer;

- taping units with dedicated Visio System for process monitoring and production data acquisition (and further SPC and FFT analysis);

- pulling units (capstan and/or caterpillar) with special solution that avoids compression of the soft dielectric;

- take-up unit with accurate cable deposition, thanks to the traversing movement of the reel;

- laser gauges before and after the taping process, for cable diameter measurement;

- loadcells and torsiometer systems to stabilize and control the tension and guarantee a highly precise line speed control.

Moreover, WTM supplies the technology for shielding with silver-plated copper tape the cable obtained with the above-described taping machine; this further, highly specialized screening machine, is specifically designed for producing coaxial cables for very high frequencies, necessary for aeronautical, instrumental and telecommunications use.

The technical characteristics can be customized according to the specific production requirements of the Customer.

Request further information or a detailed quotation now!

Information Request